- Empty cart.

- Continue Shopping

Extend the Life of Your Surgical Instruments: Sterilization & Storage Best Practices

Surgical instruments are critical investments for any medical facility. Proper sterilization and storage not only ensure patient safety but also extend the lifespan of these precision tools, saving costs in the long run. In this guide, we’ll explore the best practices for sterilizing and storing surgical instruments to maintain their functionality, prevent corrosion, and reduce wear and tear.

Why Proper Sterilization & Storage Matters

Surgical instruments are subjected to repeated use, harsh cleaning agents, and high-temperature sterilization. Without proper care, they can dull or corrode, reducing effectiveness, develop rust or pitting, leading to contamination risks, or become misaligned or damaged, requiring costly replacements. Following best practices ensures longer instrument lifespan, consistent performance, reduced repair and replacement costs, and compliance with infection control standards.

Step 1: Proper Cleaning Before Sterilization

Sterilization is only effective if instruments are thoroughly cleaned first. Residual blood, tissue, or debris can interfere with sterilization and cause damage.

Best Practices for Cleaning:

- Immediate rinsing after use prevents biofilms from forming.

- Ultrasonic cleaning helps remove debris from hard-to-reach areas.

- Use enzyme-based detergents to break down organic material.

- Avoid abrasive brushes or harsh chemicals that can scratch surfaces.

- Inspect instruments for damage or wear before sterilization.

Step 2: Choosing the Right Sterilization Method

Different instruments require different sterilization techniques. The most common methods include:

1. Steam Sterilization (Autoclaving)

- Best for: Heat-resistant metal instruments.

- Temperature: 121°C (250°F) to 134°C (273°F)

- Cycle time: 15-30 minutes

- Pros: Fast, effective, and cost-efficient.

- Cons: High heat can dull sharp edges over time.

2. Chemical Sterilization (Cold Sterilization)

- Best for: Heat-sensitive instruments (e.g., endoscopes, plastics).

- Common agents: Glutaraldehyde, hydrogen peroxide plasma.

- Pros: Gentle on delicate instruments.

- Cons: Longer processing time; requires proper ventilation.

3. Dry Heat Sterilization

- Best for: Instruments that can’t tolerate moisture (e.g., powders, oils).

- Temperature: 160°C (320°F) to 190°C (375°F)

- Pros: No corrosion risk.

- Cons: Longer cycle time (1-2 hours).

4. Ethylene Oxide (EtO) Sterilization

- Best for: Extremely sensitive instruments.

- Pros: Works at low temperatures.

- Cons: Toxic fumes require aeration; lengthy process.

Step 3: Proper Drying After Sterilization

Moisture is the enemy of surgical instruments—it leads to rust and corrosion.

Drying Best Practices:

- Use a drying cabinet if available.

- Air-dry instruments completely before storage.

- Avoid towel drying, as it can leave lint or micro-scratches.

Step 4: Correct Storage Techniques

Improper storage can undo all the benefits of proper cleaning and sterilization.

Best Storage Practices:

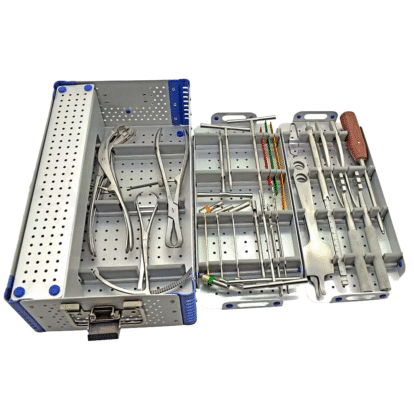

✅ Use perforated trays or cassettes to allow air circulation.

✅ Store in a cool, dry, and dust-free environment.

✅ Avoid overcrowding to prevent scratches and damage.

✅ Keep hinged instruments open to avoid tension on joints.

✅ Use silica gel packs in storage cabinets to absorb moisture.

✅ Implement a first-in, first-out (FIFO) system to rotate stock.

What to Avoid:

❌ Storing instruments while wet.

❌ Using plastic sleeves (traps moisture).

❌ Stacking heavy instruments on top of delicate ones.

Step 5: Regular Maintenance & Inspection

Even with proper care, instruments need routine checks.

Maintenance Tips:

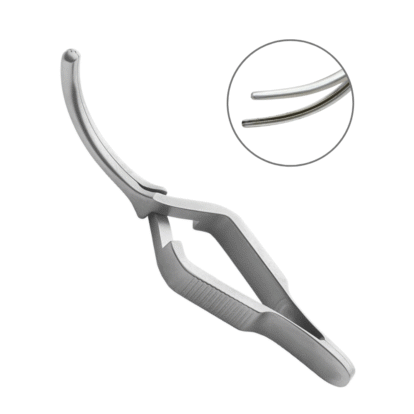

- Lubricate hinges and moving parts with instrument milk or silicone spray.

- Inspect for rust, corrosion, or misalignment before each use.

- Sharpen cutting instruments regularly to maintain precision.

- Send for professional servicing if wear is detected.

Conclusion: Maximizing the Lifespan of Surgical Instruments

By following these sterilization and storage best practices, healthcare facilities can extend the life of expensive instruments, reduce replacement costs, ensure consistent performance, and maintain compliance with safety standards. Investing time in proper care today saves money and ensures reliability for years to come.

FAQs

Q: How often should surgical instruments be serviced?

A: Ideally, every 6-12 months, depending on usage.

Q: Can I use regular lubricants on surgical instruments?

A: No—only use medical-grade lubricants like instrument milk.

Q: What’s the best way to remove rust from instruments?

A: Use a rust remover designed for surgical tools, then re-sterilize.

Q: Should I store instruments in sealed pouches?

A: Only if they are completely dry; otherwise, use breathable storage.

By implementing these best practices, your surgical instruments will remain in optimal condition, ensuring safety and efficiency in every procedure.

Need high-quality surgical instruments or maintenance services? Contact us today for expert recommendations!